Industrial reliability

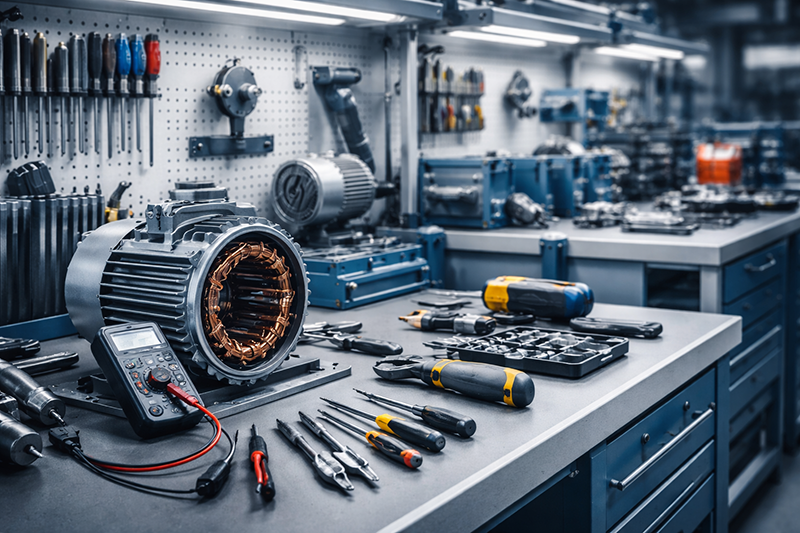

Components and assemblies designed for daily use in production and industrial environments.

Industrial solutions from Selb – from development to precise series production.

Family-run company with decades of experience in components for welding equipment.

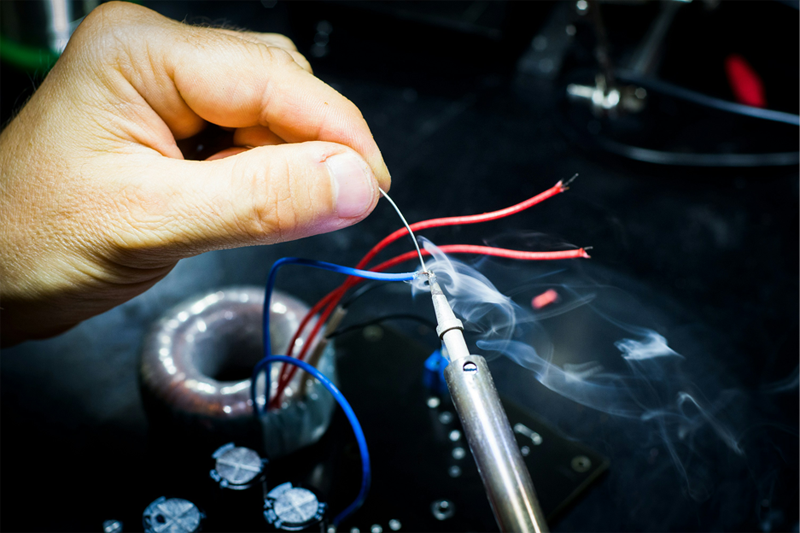

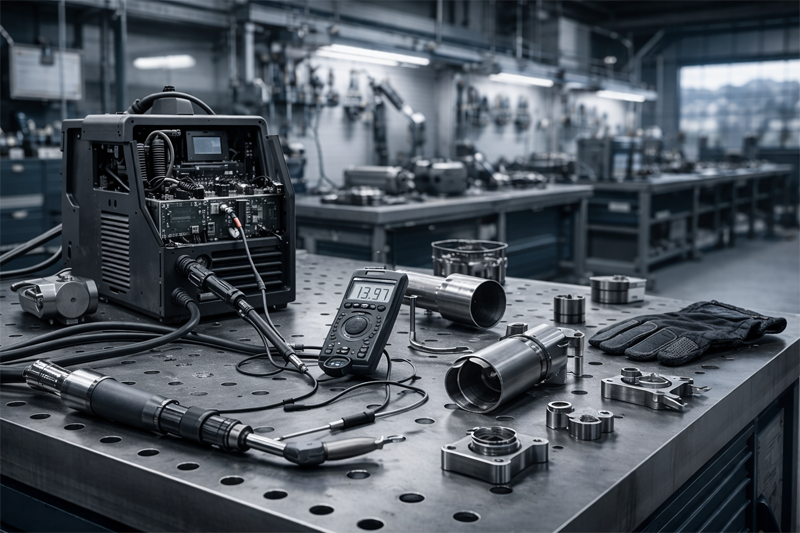

Components, assemblies and special solutions for welding equipment manufacturers.

Support from initial enquiry to series production.

Production in Selb with short decision paths and reliable delivery times.

Components and assemblies designed for daily use in production and industrial environments.

From single parts and prototypes to recurring small and medium series.

We review drawings, check feasibility and suggest optimisations where they make sense.

Wollnitzke offers a wide range of product solutions in the field of welding equipment components. Browse our catalogues or contact us directly — together we will find the right solution.

Product page is currently being revised

Device components for a wide variety of welding equipment types — precisely manufactured and designed for continuous industrial use.

Individual problem-solving and new developments — particularly in the field of welding technology.

From single part to assembly: we deliver ready-to-install assemblies from a single source — including procurement of standard and purchased parts.

You send us drawings, bills of materials or samples. We clarify open points directly with you.

We check feasibility, material, batch sizes and delivery time and prepare a transparent quotation.

After your approval we start production. Machining, assembly and inspection follow defined processes.

Inspection according to your requirements – from sampling to 100% checks. Secure packaging and shipping as agreed.

Since the company’s founding in 1978, WOLLNITZKE has been committed to progress with a strong willingness to innovate. To this day, the focus remains on the development and manufacture of high‑quality components for welding equipment.

As a family‑run company across two generations, we combine many years of experience with modern manufacturing technology. From the idea to the finished product or the ideal complete solution: thanks to our in‑house production and decades of expertise, we can respond very precisely to special customer requirements — no matter how specific they may be.

Our components and assemblies are used in various industries – wherever precise and reliable solutions are required.

Mechanical components, brackets and functional parts for special-purpose and series machines.

Parts and assemblies for handling, conveyor and testing systems.

Single parts and small series for test setups, prototypes and customised projects.

Do you have drawings, samples or a specific task? Send us your documents – we will review feasibility and get back to you with a proposal.

Send inquiry now

Briefly describe your part or project – we will get back to you with further questions or a concrete offer.